Koch Technik have upgraded their ever popular KeM dosing unit to become Industry 4.0 compliant using the OPC-UA interface enabling processors to integrate the unit into the SCARA system

Flow – temperature monitoring and control of multiple cooling circuits is now easier than ever with FlowTech.

Existing flow regulators can be updated with a digital flow meter to adjust the right flow and pressure for tighter monitoring and control.

- Tight Flow control is managed by proportional selenoid valves.

- Monitoring flow and temperature in&out of every circuit from 7” touchscreen display.

- Flowtech Software conveniently calculates cooling capacity for each cooling circuit.

- Alarm Warning such as out of temperature&flow limits per circuit can be seen from the display as well as through potential free contact in any peripheral equipment or the imm itself.

- Manifold can be connected to a network through ethernet connection. This will allow access from any remote computer.

- Flow is measured by technologically advanced sensors operating according to paddle wheel principle integrated in the

manifold system. - In&Out Water temperature is read by PT 100 sensors.

- +-1C temperature tolerance.

- Manifold is manufactured from non corrosive anodised alluminium.

To further develop itself in the field of end of arm tooling in the plastics industry, Gimaic have invested in a state of the art 3D printer for the production of custom jaws for its parallel and radial grippers . Along with this custom brackets or fixtures can be produced.

- Maximum printable dimensions 284x380x380 mm.

- Material PA12

- Similar mechanical features of moulded parts

- Shipping in 48 hours

- Customer Library is kept for easily repeat ordering

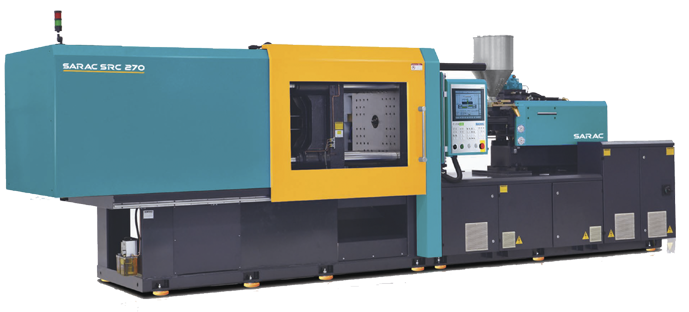

Geiger Handling have been extremely happy to have welcomed Sarac to the UK this week to visit new and existing customers alike. There will also be exciting news in the coming weeks that will add 2 further machines to their already broad portfolio of Servo technology injection moulding machines

- Compact

- User friendly

- Industry 4.0 ready

- Color touch screen display

Malton Plastics recently invested in a new 350 ton Demag to fulfill their ever increasing production demands, along with this they took the decision to invest in a linear robot for the removal of mouldings from the press , Geiger Handling supplied a turnkey solution of a Wemo E-design robot safety guarding and conveyor belt . Since installation Malton have seen an increase in production output and quality due to stable cycle times compared to having the machine manned by an operator

To read more please follow this link

With the introduction of the 250 eLine with maximum 25kg handling weight, it is ideal for IMM’s up to 1000 tons

eLine

This range of robots stands for economy,efficiency and energy saving. These are the most important factors for an investment to be competitive in production.

Optional Functions

It is possible to equip the e-Line robot range with several useful options for high flexibility. Wide range of axis extensions, telescopic vertical axis, additional rotation axis and up to 4 vacuum and 4 gripper circuits.

Flexibility

The robot range is used AC servo motors in all three axes for simultaneous movement, ensuring speed and with high precision. This is important for inserting of parts or assembly operations. The planetary gearboxes result in maximum output efficiency.

Geiger are proud to announce the introduction of the Sarac Speed line of Injection moulding machines , with clamp forces from 270 to 400 ton and with impressive injection rates of 400mm/s make it the perfect choice for thin walled applications such as packaging and consumable items where high speed are required. Follow this link to find out more Injection Moulding Machines

Geiger Handling Ltd welcomes you to our new website! Thanks to the team at Limelight for their hard work creating this. We hope you will find all the injection moulding equipment information you need on our new site and if there’s anything you can’t find, please don’t hesitate to get in touch.